Green Hydrogen Production

We are able to supply PEMWE CCM and stack. Alkali liquid electrolyzer and customized system according to the actual conditions of the end user.

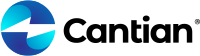

Proton Exchange Membrane Electrolysers

Proton exchange membrane electrolyser cells have been available commercially for many years, but historically not at a large enough size to be suitable for energystorage. Recently, a number of companies have announced their intention to developlarge-scale electrolysers and target this market.

PEMEC have fast response times to fluctuations in electrical input and they can also be operated anywhere between zero and 100% of nominal capacity (or higher for short periods); these are important considerations if the technology is to be considered for grid balancing. PEMEC also produce high-purity hydrogen, which can be used directly in many applications with no further purification required. The technology allows for operation under differential pressure, meaning hydrogen can be produced at a higher pressure than oxygen.

Current drawbacks to PEMEC include their relatively high capital cost, resulting from the use of expensive membranes and electrode materials, and their unproven durability and scalability. The modular nature of these systems may help to overcome problems of scale to some extent.

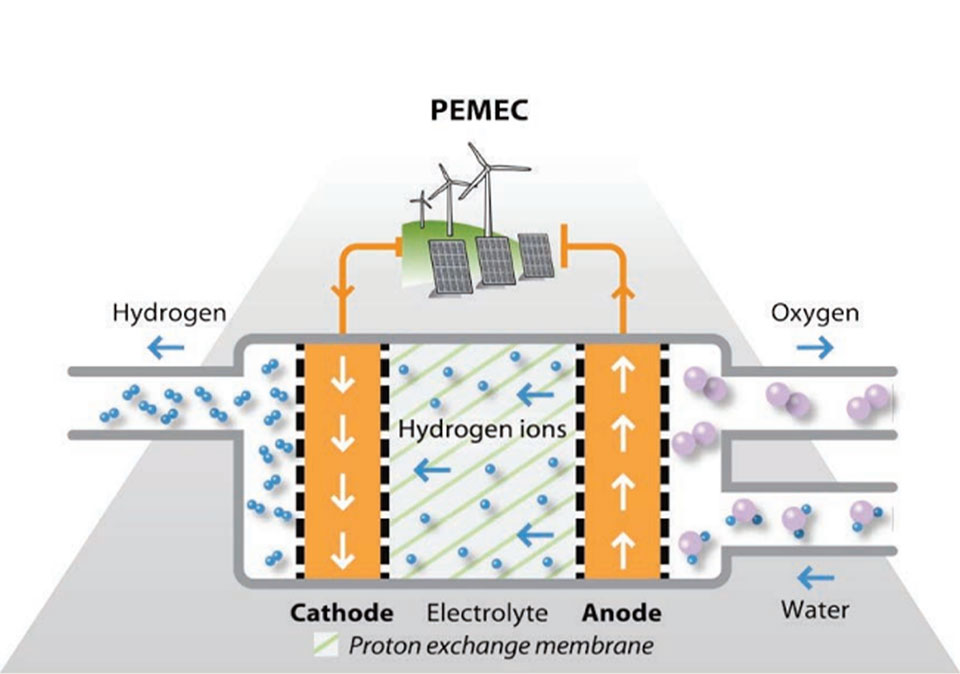

Alkaline Electrolysers

Alkaline electrolyser cells have been in commercial use in industrial applications since the 1920s and it iS the most mature electrolyser technology available today. The electrolyte is an aqueous alkaline solution containing either sodium hydroxide (NaOH) or potassium hydroxide (KOH) and electrodes are commonly made of nickel-coated steel.

AEC technology is well understood and has a reputation for being robust, with units in reliable operation for decades. It is the current standard for large-scale electrolysis and systems have been successfully built at megawatt-scale, producing up to 200 Nm3/h of hydrogen, making them well suited to the storage of large quantities of energy. AEC also tend to use cheaper materials than PEMEC, due to their alkaline chemistry, which is also a consideration when raising the capital for a new installation.

In energy applications, conventional AEC technology may have drawbacks, such as a relatively limited ability to respond to fluctuations in electrical input, something commonly found when integrating renewables such as wind and solar. To produce gas at pressure, the entire unit needs to be pressurised, adding cost. Gas purity is also lower than with PEMEC technology, as traces of the electrolyte remain which must be scrubbed out in order to produce hydrogen of the necessary purity. These limitations are the subject of technology development aiming to improve the performance of AEC when linked to renewable energy, and new products targeting this application are being released.